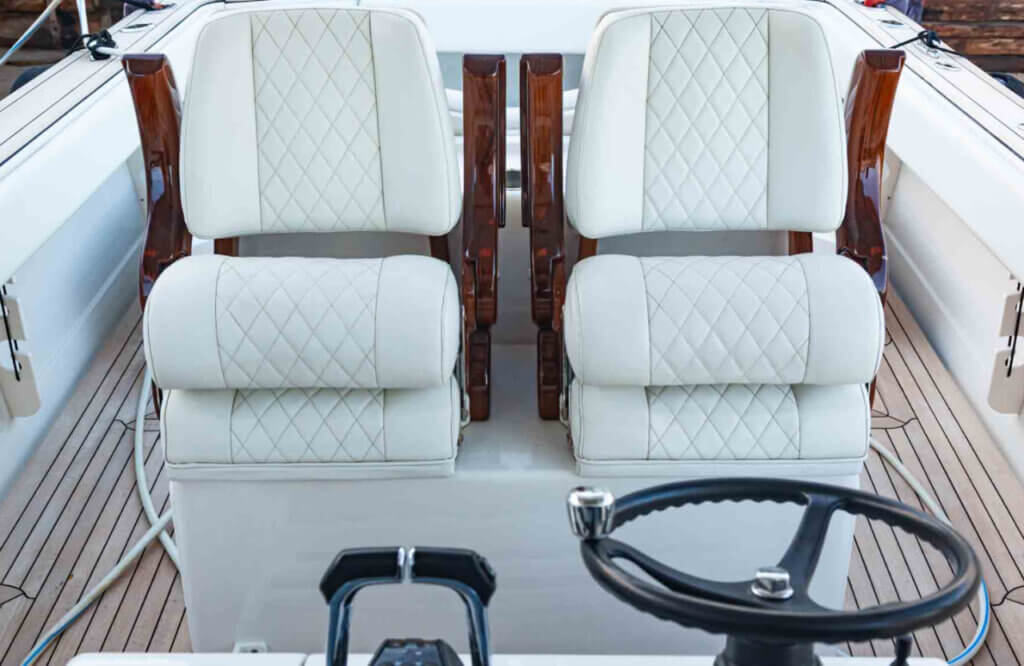

Giving your boat fresh upholstery can transform its look and feel, but understanding true reupholster boat seats costs takes more than a glance at fabric prices. Material quality, labor complexity, foam condition, and custom touches all combine to define what you’ll pay. This guide dives into each expense category, showing you how to break down your project so you can anticipate costs, compare quotes confidently, and avoid unwelcome surprises.

Material Expenses

Fabric and vinyl make up roughly half of most reupholstery bills. Standard marine vinyl remains the most popular choice thanks to its balance of durability, price, and ease of cleaning. Premium vinyl varieties add UV inhibitors or textured surfaces and command a higher rate, while woven marine fabrics deliver a softer feel but require specialized care.

- Standard marine vinyl: $20–$28 per yard

- UV-resistant premium vinyl: $30–$45 per yard

- Marine-grade woven fabric: $38–$60 per yard

- Specialty prints or faux leather: $55–$100 per yard

Estimate total yardage by measuring each cushion’s width and length, then add a 15 percent buffer for pattern alignment, seams, and trial cuts. Boats with bench seats and simple shapes may need 5–8 yards, whereas wraparound lounges or sculpted helm chairs often demand 10–14 yards.

Labor and Installation

Labor typically accounts for 30 percent to 45 percent of total outlay. Experienced marine upholsterers charge between $60 and $90 per hour, with rates rising in coastal metropolitan areas. The time required hinges on cushion complexity, foam removal, and frame condition.

- Bench seat covers: 2–5 hours each

- Captain’s chairs with bolsters: 7–10 hours

- Wraparound lounges and corner seats: 10–15 hours

- Foam replacement or minor frame repairs: +1–3 hours per cushion

Before work begins, confirm whether labor quotes include foam removal, frame inspection, and seam sealing. Transparent billing practices ensure you know exactly what labor hours and tasks are covered.

Foam Replacement and Frame Repair

Old or waterlogged foam undermines seating comfort and accelerates fabric wear. High-density closed-cell foam costs $18 to $35 per cushion, depending on thickness and brand. If your boat’s seat frames show rust, rot, or warping, plan for basic repairs wood straightening, metal welding, or reinforcement panels at $25 to $60 per section.

Skipping necessary foam or frame work might lower your upfront estimate, but neglecting these elements often leads to rapid upholstery failure. Be ready to add these figures into your budget before fabrics go on.

Custom Details and Add-Ons

Personalizing upholstery with piping, embroidery, or accessory pockets elevates style but raises costs. Carefully consider which accents deliver the greatest visual impact for the smallest premium.

- Embroidered logos or monograms: $75–$250 each

- Contrasting piping: $2–$6 per linear foot

- Integrated cup holders or phone pocket panels: $20–$60 apiece

- Quick-drain backing cloth or waterproof zippers: $10–$25 per seat

Limiting custom touches to one or two focal cushions helps contain expenses while still giving your boat that bespoke finish.

Geographic and Seasonal Factors

Regional demand and seasonal cycles directly influence pricing. Upholsterers in Florida, California, and other boating hubs often charge 10–20 percent more than shops inland. Likewise, high demand in summer can push lead times to several weeks and sometimes higher peak-season rates. Scheduling your reupholstery in late fall or early spring may secure off-peak discounts and faster turnaround.

Sample Budget Breakdown

Rather than relying on broad averages, build your own cost framework by combining material estimates, labor projections, and add-ons. For a midsize runabout with two bench seats and one helm chair:

- Material (9 yards premium vinyl / $40): $360

- Labor (18 hours / $75): $1,350

- Foam replacement (3 cushions / $30): $90

- Piping (20 ft / $4): $80

- Embroidery (1 logo): $150

- Travel fee: $50

Total: $2,080

Adjust these line items to match your fabric choice, local labor rates, and project scope. This transparent approach keeps you in control of your reupholster boat seats costs.

Tips for Cost Control

- Request detailed written quotes from at least three upholsterers.

- Opt for in-stock fabric colors to avoid special-order premiums.

- Replace foam only where it’s compressed or damaged.

- Bundle foam repair and frame work into one contract for package pricing.

- Time your project during shoulder seasons for potential rate reductions.

Open dialogue about your budget often inspires upholsterers to recommend creative cost-saving alternatives without sacrificing quality.

Final Considerations

Accurately estimating reupholster boat seats costs means accounting for every variable from yardage buffers to labor complexity and hidden repairs. By quantifying materials, projecting labor hours, and isolating add-on charges, you form a clear picture of what your upholstery project will require. Armed with these insights, you can negotiate fair deals, avoid last-minute markups, and ensure the upgraded seating on your boat delivers both comfort and longevity.